MITUTOYO - CNC Roundness/Cylindricity Measuring System : ROUNDTRACER EXTREME | JSR GROUP

CNC Roundness/Cylindricity Measuring System

ROUNDTRACER EXTREME

|

ROUNDTRACER EXTREME All- In - OneA high-end machine that integrates roundness, contour, and surface roughness measuring functions all in one. This measuring machine not only delivers speed, accuracy and operability at the highest level, but also supports the measurement of workpieces of various shapes, such as |

|

|

High-throughput roundness measurement |

High-accuracy contour measuring |

Even more advanced surface roughness measurement |

1.Improved Flexibility

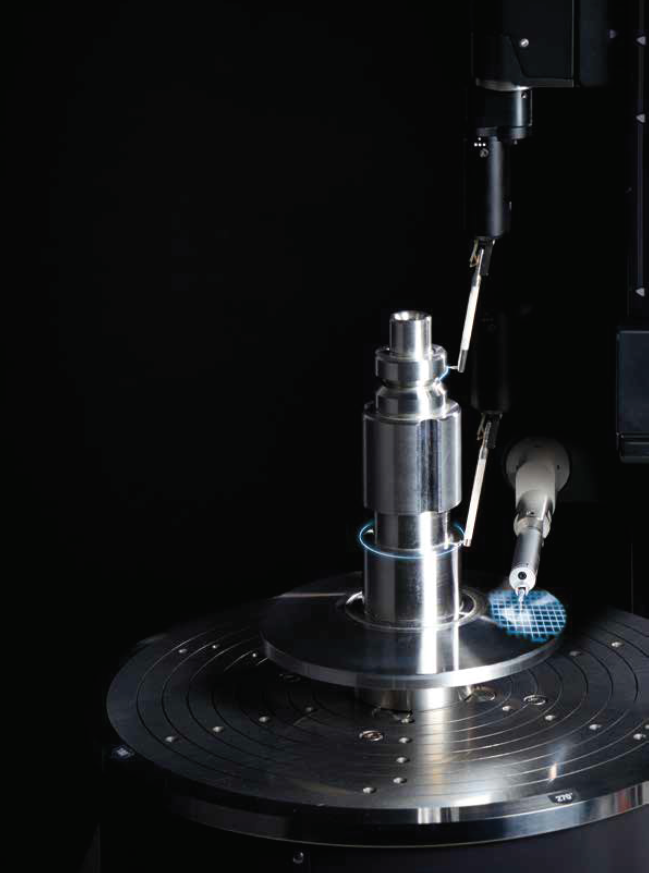

Newly developed motorized sliding axis, detector, and detector holder help avoid workpiece interference while enabling continuous automatic measurement

A motorized sliding axis, and a detector and detector holder capable of changing the stylus angle (0°, 10°) have been newly developed to enable measurement while avoiding workpiece interference.

|

Motorized sliding axis

Easy measurement of inside diameter for thick workpieces A 3-step motorized sliding axis enables easy inside diameter measurement of thickworkpieces by avoiding interference, without having to replace the stylus as in conventional models. Furthermore, it allows for continuous automatic measurement of squareness, runout, etc. by combining inside diameter and upper surface measurements. |

Detectors

Continuous small hole and outside diameter measurement Allowing the stylus angle to take 2 states, 0° or 10° enables continuous, combined measurement of small holes and outside diameters while avoiding workpiece interference. Furthermore, measurement can be conducted with the workpiece remaining in the same position when measuring repeatedly while changing the stylus angle since changes in stylus tip position are automatically recognized by ROUNDPAK. |

2.Improved Drive Speed

Dramatically improved measurement throughput by reduced positioning times

Best in class maximum X, Z, and θ axes drive speed. Greatly reduced positioning times compared with conventional models. Moreover, throughput has dramatically increased for curvilinear measurements since data can now be acquired independently of the turntable 0° position.

|

X and Z axes drive speed

Best-in-class maximum of 100 mm/sec. With improved positioning accuracy and greatly reduced positioning times compared with conventional models. |

θ axis drive speed

Best-in-class maximum of 30 rpm. The ability to acquire measurement data without waiting for the 0° position in curvilinear measurements reduces the positioning time by about 40%b compared with conventional models (in-house comparison), dramatically improving the performance. |

3.Improved Repeatability and Reproducibility

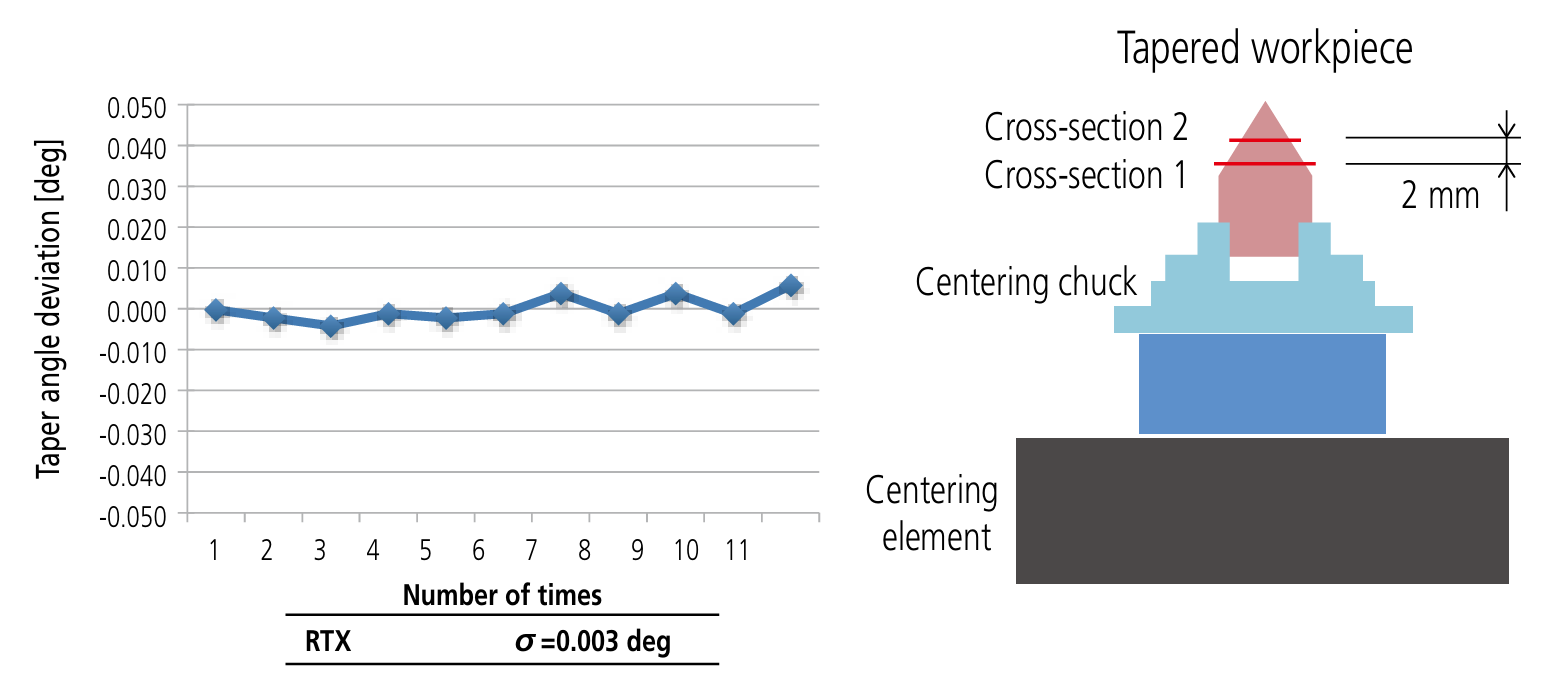

Highly reproducible measurement as a result of new centering table architecture

The new centering table architecture reduces positional changes of the workpiece during measurement. Improved positioning accuracy of X and Z axes greatly increases measurement reproducibility compared with conventional models.

|

Internal architecture of the Z axis slider Internal architecture of the table |

|

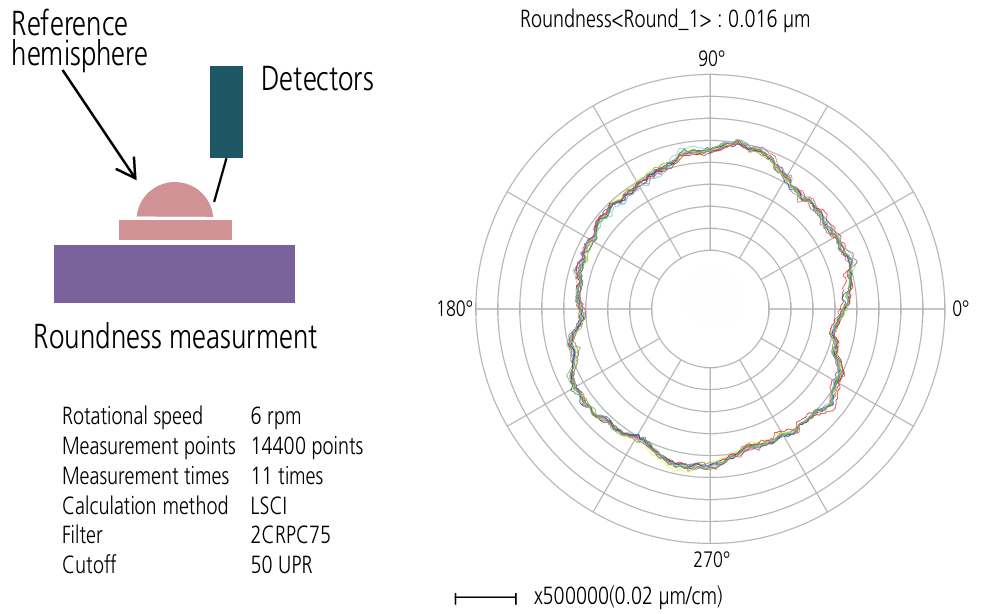

Result of repeating roundness measurement 11 times on reference hemisphere

|

Repeatability of tapered workpiece measurement

|

4.Rich Additional Features

Pursuing functionality from the viewpoint of users

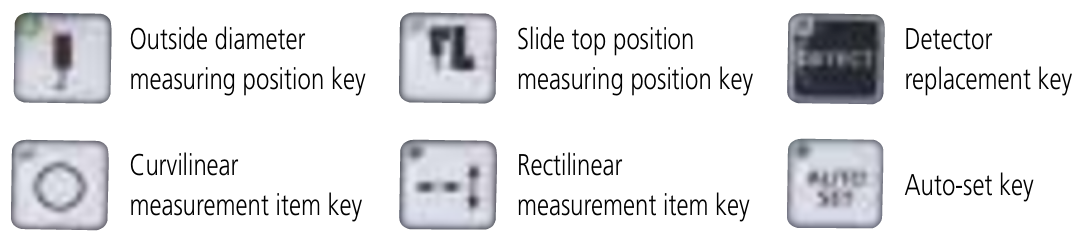

Design delivering both usability and innovation.The ergonomic remote box enhances the user’s experience with clearly laid out buttons and controls.

Remote box

|

Provides excellent operability as a result of newly added features, such as the override control that enables drive speed adjustment in real time, and the part program key that assists the creation of part programs.

|

Additional measuring functions

|

Form/contour |

Surface roughness |

Lead (twist) analysis |

ROUNDPAK

Provides a wide variety of parameters as standard features, including those for roundness/cylindricity, as well as flatness and parallelism.

|

Allows for switching to measurement-only screen (run-only measurement screen), where operators are only allowed to run part programs. |

Equipped with an offline teaching function, part programs can be created without even having actual measurement workpieces, and measurements can be virtually run in the 3D workpiece view window. Warnings regarding risk of collision can also be displayed. |

Allows for setting of X and Z axes travel ranges to prevent collisions with workpieces as a result of operational errors.Travel ranges can be grasped at a glance by displaying the software limit information bar on the measurement control screen. |

|

Allows for removing abnormal data in the measurement data (by mouse operation) due to scratches, dust or other contamination on the workpiece, which affect the analysis results. In addition, there is also a function to automatically remove abnormal points based on set thresholds. |

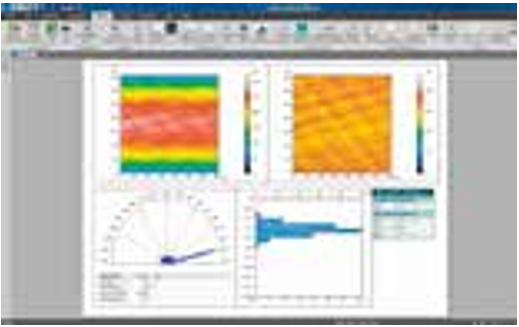

The customer can create measurement reports in custom formats by specifying how the analysis results will be displayed, as well as the sizes and positions of graphics. |

FORMTRACEPAK-AP

Contour analysis, surface roughness analysis and the creation of inspection certificates are included as standard features.

|

Contour analysis

Provides not only a range of basic commands for analyzing points (10 types), lines (6 types), and circles (6 types), but also a wide variety of commands to calculate angles formed by a combination of items, pitches, distances, etc., contour matching function, and design value generation function as standard features. |

Surface roughness analysis

Allows for surface roughness analysis according to standards, such as ISO, JIS, ANSI, VDA, etc. Provides a wide variety of functions not only for calculating parameters, but also for analyzing various graphs, removing (compensating) shapes such as slopes and curves, removing data, etc. |

Layout

Allows for layout of contour, surface roughness, and/or roundness measurement results and graphics on a single sheet of paper by using simple operations. Furthermore, support for pasting from specified saved files allows results to be pasted from multiple files. |

MCubeMap

Visualizes analyzed surface roughness and contour by using a wide variety of graphic technologies.

|

Wide variety of data operation functions

Allows for visualizing the measurement target in |

3D parameter analysis

Supports the latest ISO 25178 3D surface texture parameter specifications. Allows for easy creation of reports with freely laid out results of analyses related to not only vertical directions, such as Sa and Sq, but also spaces, compounds, features, and graphics. |

Lead (twist) analysis

Supports the lead (twist) analysis used for assessing the sealing performance of shafts |

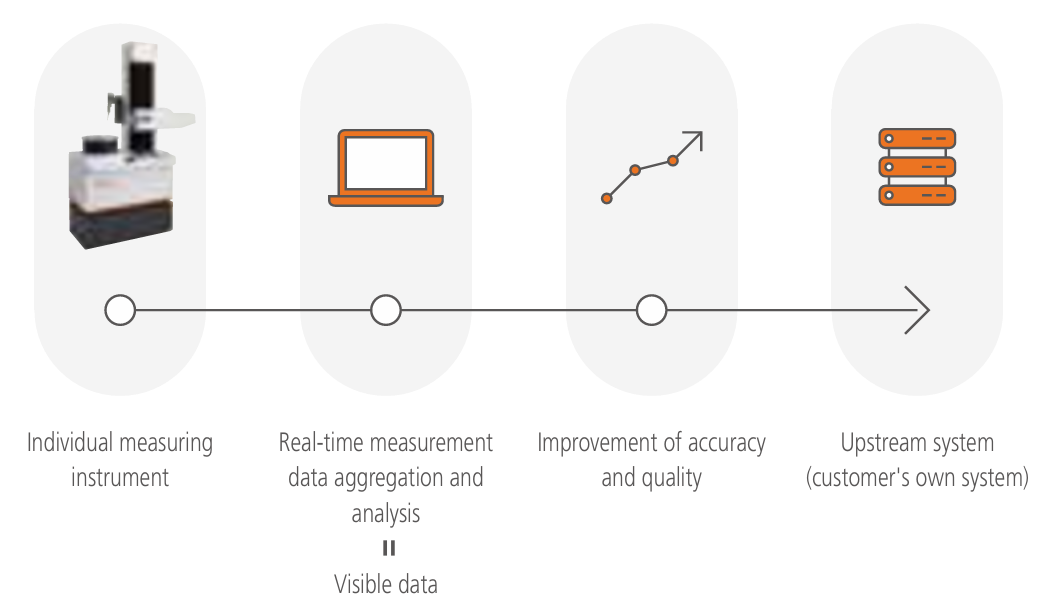

MeasurLink

|

Reduction of defective products by “visualize product quality” Measurement results enable various statistical processing operations. Furthermore, displaying the control chart in real time enables early detection of possible future failures (cutting tool wear, damage, etc.). In addition, connecting this program to an upstream network environment as a terminal enables the construction of a system for centralized management. |

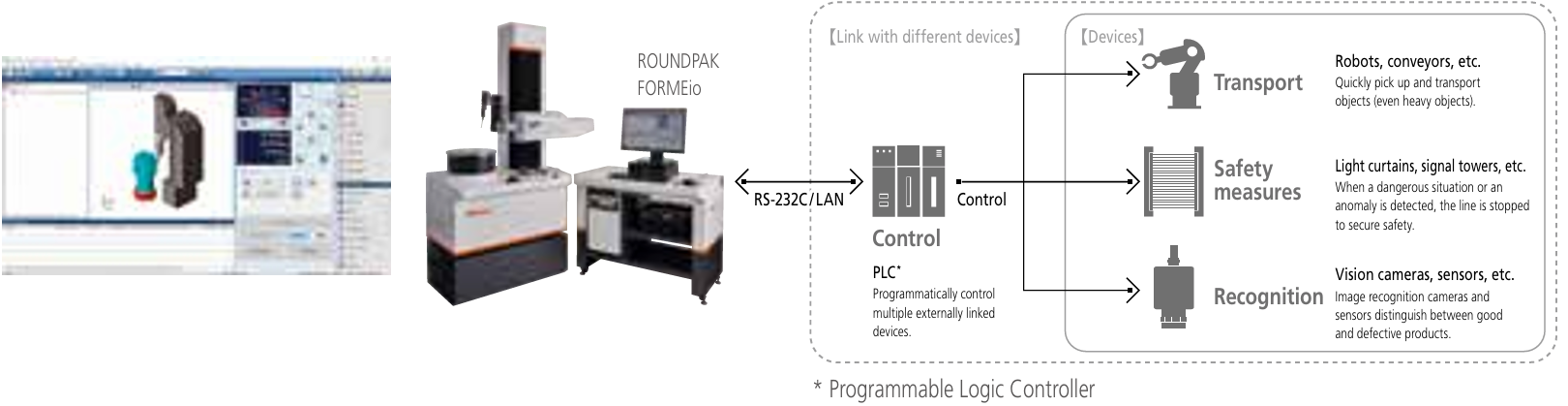

FORMEio

This is optional software for installing the external control function in the measuring instrument.

Remote status monitoring and control

With this function it is possible to monitor and control the measuring instrument conditions via RS-232C/LAN communication from the PLC (Programmable Logic Controller).

Efficient precision measurement for practically any workpiece

ROUNDTRACER EXTREME has applications supporting measurements for a wide variety of workpieces. It delivers efficient, high-precision measurements, such as continuous measurement of inside diameter and upper surface of thick workpieces owing to the motorized sliding axis, or automatic recognition of the stylus tip position during continuous measurement of inside and outside diameters of small holes.

APPLICATION

|

Camshaft

Camshafts require high-precision measurement because they control the opening and closing of inlet/outlet valves that improve the combustion efficiency of engines. Measurement of cam shape, surface roughness, and roundness, which previously required multiple measuring instruments and setup, can now be efficiently conducted using a single measuring machine. |

Tool holder

The tapered portion of tool holders requires high-precision measurement since it needs to pair with the main axis of machine tools. High-precision positioning by the newly developed centering element and Z axis slider enables highly reproducible measurements.

|

|

Bearing

The surface roughness of bearings requires high-precision measurement since it has direct impact on the coefficient of friction. A single ROUNDTRACER EXTREME can not only efficiently measure roundness, but also surface roughness with high accuracy. |

Pulley based CVT

Pulley based CVTs are components of automotive continuously variable transmissions that contribute to fuel efficiency and smooth travel. Measurement of surface roughness of the tapered portion, roundness, and contour. This previously required multiple measuring instruments and setup but can now be efficiently conducted using a single measuring machine. |

|

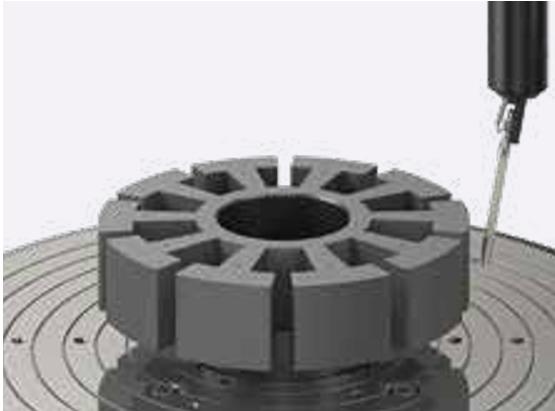

Electric motor cores

Motor cores, which are the base of motor assemblies, require high machining accuracy. ROUNDTRACER EXTREME allows for efficient, high-precision workpiece setup for rectilinear contour measurement at multiple points. |

Spline

The rotating X-axis tracking measurement function enables all-round measurement and assessment* of splines exceeding the measuring range of the detector. |